The QuinLogic mission is to create additional value for steel industry quality processes through data processing.

Our focus is on key value drivers:

- Improving revenues (upgrades, reassigns)

- Cost reduction (material, energy, labour)

- Increased yield (uptime, throughput, quality)

QUINLOGIC is a team of experienced professionals who have worked through the last decade with the industry to improve product quality and production processes. We understand our customer’s requirements. We understand that software methodology independent of a particular gauge would unleash further benefits for our customers

Software: Quality Assurance

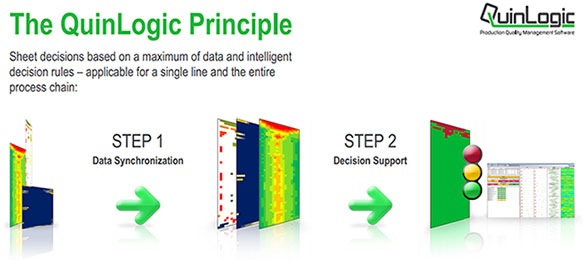

Understanding our customer’s needs, we have started our product roadmap with rule-based decision software. With many decisions involving a multitude of information, we work with gauge manufacturers worldwide to ensure data integration

Decision support can be used for product qualification and certification as well as re-assignment or re-routing. The same data can be used through additional QuinLogic software for product or process review and for trouble shooting and root cause analysis

The QES (Quality Execution System)

QuinLogic provides a revolutionary total quality assurance solution for “high end” steel and aluminum mills, which meanwhile has turned out to be the industrial standard in many well-known production sites worldwide. This innovative software product based on the quality execution system (QES) software suite offers better and more reliable quality for the challenging markets e.g. for the automotive-, airplanes-, wind energy-, high strength- and wear resistant material grades. Its seamless communication interfaces to existing MES, ERP and gauging systems allows fully integrated systems in all existing but also new production lines

The key features of a Quality Execution System (QES) are to track quality including decision support per individual piece produced, exchange sequence related information with the MES and ERP systems and feed process related information back into the set-up for the next piece. From all these activities, decision support is obviously the most important and critical activity, given the amount of investments into advanced monitoring and gauging over the recent years